Description

The Screw Type Injector Plunger I-100SM, 12030, is a robust and well-built windscreen repair tool that is virtually “bulletproof” and has 4 impressive features:

- Manufacturing excellence, high-sheen stainless-steel polish surfaces I-100S injector plunger. The stainless steel provides for smoother operation.

- Superior tooling providing excellent fit and function.

- Knurling has been retained in key grip areas, but is less pronounced for improved comfort.

- Minimal threads on the outer piston make for fast operation and less resin waste.

Use the Screw Type Injector Plunger with a variety of Delta Kits bridge assemblies. The three components of this windscreen repair injector are the plunger (male part), the cylinder (female part) and the injection molded end seal.

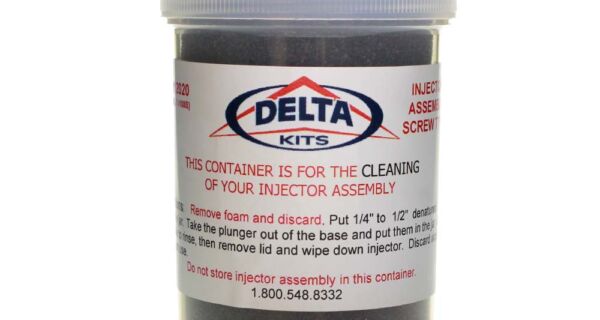

Also includes a 22435 Cleaning Jar & Cap.

Replaces Part Number: 1-100SM

From the Archives

Tech Tip: Don’t Take your Injector Seals for Granted!

If you can remember to change your injector seal after every 10 windscreen repairs, it will help you avoid increased repair times, wasted resin, and most of all, poor quality repairs. Read on, and you will learn even more about injector seal replacement.

Q: Why should I change the injector seal after every 10 repairs?

A: After 10 repairs, the inside walls of the seal begin to wear. This can allow resin to blow past the piston and up into the injector while you are applying pressure to the damage. When this happens, even though the seal is not visibly leaking, your pressure and vacuum cycles will be less effective. This opens the door to poor quality windscreen repairs.

Q: Should I flip the injector seal around? Use it the other way to get more life out of it?

A: No. It’s not typically the end of the seal that wears out. So, there would be no benefit to switching ends, even if they were the same. Look carefully at both ends of the seal. Notice a stamp that reads “This Side In” on one end. That side is not a flat surface, due to the text on the end of the seal, meaning it will not seal properly if that side is placed against the glass. Both ends are not the same, but the differences are subtle enough that many technicians may not notice the difference without that writing.

You will also notice on the end of the seal with the writing that the hole is flared out slightly. This is to make the injector slide in easier. On the end of the seal that touches the glass, the hole is tapered in slightly to create a bit more pressure just as the resin enters the break, and to help prevent leaking. READ MORE ->->

Reviews

There are no reviews yet.